Eagle’s Nest

Setting a new benchmark for sustainable mining Canada.

We are advancing the Eagle’s Nest Project In partnership with First Nation communities, incorporating industry-leading technologies to produce high-grade clean critical minerals needed for the clean energy transition.

Highlights of the Eagle’s Nest Project include:

An initial 12-year mine life, with a potential eight-year extension.

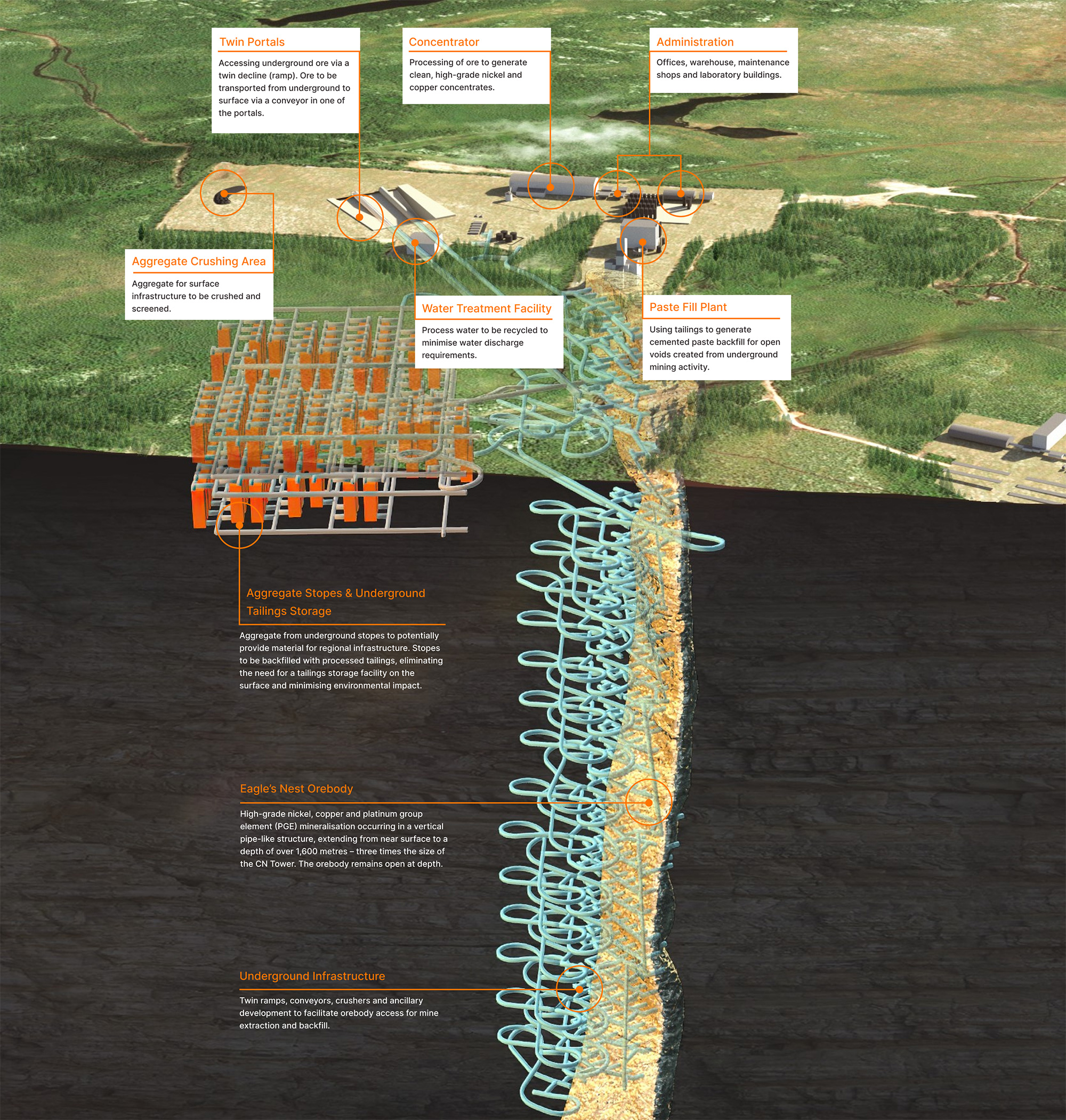

Traditional 3,000 tonne per day underground mine operation (blast hole open stope).

Incorporating paste backfill to store 100 per cent of tailings underground to minimise surface disruption.

Annual production output of 15,000 tonnes of nickel, in addition to 6,000 tonnes of copper, 70,000 ounces of palladium and 22,000 ounces of platinum.

Mineralisation occurring in a near-vertical pipe-like structure, which extends from near surface to a depth of over 1,600 metres – three times the size of the CN Tower. The orebody remains open at depth.

Nickel production from Eagle’s Nest

could sufficiently supply batteries for

250,000 electrical vehicles each year

Not to scale

Artist render

Our path to development

We are working with the Federal and Provincial governments on permitting and approvals. With an expedited and whole-system approach, the same meticulous planning and quality of execution that is going into our mine design is being applied to all aspects of assessment, consultation and permitting.

Development of a regional infrastructure corridor providing all-season road access, led by First Nation communities, is key to unlocking the Eagle’s Nest deposit.

Sustainable mine design

The Eagle’s Nest Project has sustainability at the heart of its design.

We are extending ourselves beyond the status quo by adopting the latest processes and technologies that include:

- A development footprint of approximately one square kilometre and a commitment to ensure much of the mine design is on uplands (not peat), mainly on the existing Esker Site.

- A minimal surface disturbance with no surface quarries, no open pits and no waste rockpiles. This reduces dust generation, visual impact, inundation risks and potential run-off of pollution.

- The first mine of its kind where 100 per cent of tailings will be stored underground, used to backfill underground ‘voids’ created from extraction. Aggregate rock from the underground stopes can potentially supply material for regional infrastructure.

- Process water recycling facilities to minimise total water usage and discharge of mine effluent.

- A comprehensive environmental monitoring program to observe for any impact to biodiversity, water quality, wetlands and aquatic life.

- A goal to avoid large bodies of water and enacting a species-at-risk impact mitigation plan developed by independent ecological consultants.

We are also investigating the use of other sustainable technologies to complement the existing mine design, including:

Grid power supplied by developing infrastructure.

Electric vehicles and hydrogen-fuelled haulage truck fleets.

Wind, solar and biomass energy as a renewable source.

Ultramafic waste rock to capture and sequester carbon.

Aiming to be the first mine globally to apply innovative techniques that will create a stable tailings solution all underground.

Partnering with local First Nation communities

We are building the Eagle’s Nest Project with First Nation communities through a co-management approach by forming genuine partnerships and mutual collaboration.

We currently have a Memorandum of Understanding (MOU) signed with two First Nation communities: Marten Falls and Webequie and are working toward Partnership Agreements that will provide long-term economic development opportunities.

By participating in the economic benefits of our operations, we believe development in the region represents a generational opportunity for northern Ontario’s First Nation communities to achieve economic empowerment in this decade.

Read more about how we are partnering with First Nation communities.

SustainabilityOur commitments

Providing Indigenous training and employment programs that guarantee employment upon completion of the program.

A minimum of CAD$100 million in contract awards to Indigenous-led businesses.

Find out more about the Eagle’s Nest Project

Read more

KEEP UP TO DATE

Subscribe

Eagle's Eye is our quarterly community newsletter that provides updates on the work we are doing at Eagle's Nest.